At arrangement of paths and paths the tile is most often used. It is easy to explain: the material is quite inexpensive, has a long service life, beautiful appearance. Moreover, any person can carry out the installation, since it is quite simple, the main thing is to strictly observe the technology.

Types of tiles, tips on choosing

The choice of tiles depends on the financial capacity of the owner of the site, because quality is quite expensive, too cheap is of low quality and fragility. In the modern market you can find products made from the following materials:

- natural stone (soft or hard rocks);

- fake diamond;

- ceramics;

- concrete (monochrome and color).

Most often, the laying of tiles in the country choose products from concrete mixtures: this material is suitable in price and quality.

Most often, the laying of tiles in the country choose products from concrete mixtures: this material is suitable in price and quality.

They are made by a method of vibropressing (tile is durable, frost-resistant, but not the brightest in color) or vibratory casting (products are characterized by a bright shade and a smooth surface).

Also on sale you can find stamped tiles, but with it you need to be careful: often these products are of low quality, quickly crumble. The important point is the thickness of the tile. With it you need to decide in advance. For example, for walkways it is better to choose tiles with a thickness of about 4 cm, for parking - at least 6 cm.

Preparatory work

Before you start work, you need to buy the following materials:

- borders (stone or plastic);

- cement (it is better to choose the brand PC400);

- crushed stone (minimum fraction - 4 cm);

- river sand;

- geotextiles.

Track marking

It is best to take a copy of the plot plan, where you need to schematically arrange the house, other buildings, trees, flower beds, a vegetable garden, and already draw a path on it. But also when drawing up the scheme take into account the direction of the slopes for the removal of water from the paths.

When determining the width of the tracks, consider the fact that two people should calmly disperse on it - that is, the width should be 1.2 m on average.

If you make a track for a car, keep in mind that a car must pass over it and a person can quietly pass.

After you have completed the plan, you can proceed to the main layout on the site, for this you will need pegs and a rope. Pulling the rope, add 10 cm to each side: this will be the distance to install the curbs.

Excavation

The volume of earthworks is largely dependent on the top layer. For example, if the surface is a layer of dense clay, in connection with which it is necessary to import bulk soil anyway, then you just need to level the surface. In all other cases, you will need to remove at least 30 cm of the upper layer around the perimeter of the track.

Pour a thin layer of sand on the bottom of the trench and carefully tamp it down, lay the geotextile on top, which is necessary to stop the growth of weeds and divert water.

Moreover, the material strips need to be laid overlapped so that one layer goes to the second at least 15 cm, at the edges of the material’s turnout must be at least 20 cm. If these rules are observed, tile laying will be of the highest quality and durable.

Drainage

On top of the textiles lay a layer of rubble with a thickness of 15-20 cm, it will be the drainage necessary for the removal of melt water. Thus, the drainage layer will prevent the accumulation of moisture: in the winter, this minimizes the risk of swelling of the path. Crushed tamped, and then sprinkled with a layer of sand. On top also lay a layer of textiles.

Rubble should be well compacted and sprinkled with a thin layer of sand. A second layer of geotextile should be laid on top of the drainage. It will pass moisture down, not allowing it to rise to the top.

Curbs

The method of fixation depends on the material of the curb:

- stone - on cement mortar;

- plastic - on special wedges.

Laying paving step by step

Base

When laying can not do without a quality base. There are three options:

- concrete;

- tamped sand;

- cement-sand mixture.

Universal can be called cement-sand base. But the base in the form of simple sand is best used with small loads on the track, the absence of ground movement.

If you decide to make a concrete base, then you first need to carry out reinforcement, for which it is better to use a metal grid (it is advisable to take a material with cells 10 cm). But you can also use the remnants of pipes, wire and other metal products. Moreover, the grid or products is best to lift above the drainage layer by 3-4 cm, for example, by laying down stones or bricks.

The height of the concrete layer should be about 10 cm, and it should be about 3 cm below the top layer of soil - you need to leave space for laying tiles. If the depth after laying the drainage remains large, it is necessary to pour sand. For the preparation of concrete mix for the base you need to take cement, crushed stone and sand in a ratio of 1: 5: 3.

Pour the prepared mixture at a time. If you plan to make a long path, for convenience and to save time, it is better to order the delivery of the mixture into place, even if it comes out a bit more expensive. Lay tile in 3-5 days, as long as the base is completely dry.

If you choose a cement-sand base, then you must first prepare the mixture, taking the cement and sand in a ratio of 1: 5. The thickness of the base is at least 10 cm. And in order to reach the required level, you need to pour sand on top as needed.

The main thing is that when working, all the material is dry. Therefore, if it has rained, wait 2-3 days for the base to dry. After that, tamp the mixture again, level it and proceed with the installation.

At arrangement of the sandy basis it is the best of all to take career or river sand. The main thing is that it does not contain impurities of clay or lime. Pour it with a layer of 12-15 cm, carefully pour water, tamp well, do not forget to align and you can lay tile.

Processing products

Before laying, treat the tile with a special hydrophobic composition that will protect the products from moisture, increase durability, frost resistance, give the products a more attractive appearance, protect them from fungus and mold.

To carry out the work, you need to dip each tile in the composition, and twice: after the first time, you need to allow the material to dry out, after which the processing is repeated.

Laying tiles

If you choose to lay on a concrete base, then you need cement mortar to fix. Moreover, the product must be laid in such a way that it fills the seams to the maximum (their thickness should not be more than 3 mm).

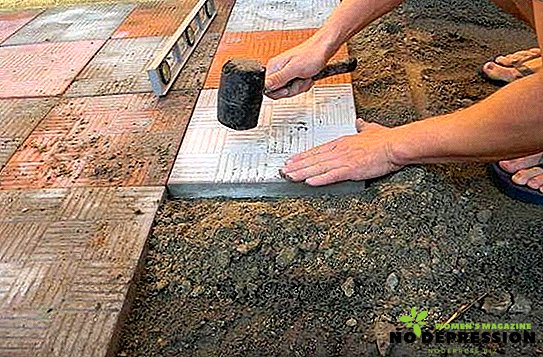

Align and adjust the tile with a rubber hammer, check the construction level. And you need to "move" the clutch on yourself: that is, you need to always be on the already laid base, pouring cement mortar in front of you. Having completed the work, be sure to grind all the seams with the mortar, this will allow you to create a monolithic coating.

Laying on a sandy or cement-sand base is the same: the work is carried out "on itself", that is, you need to move on the surface and lay the product in front of you. If necessary, you need to pour or remove sand. And in order to fix the tile as securely as possible, it is necessary to knock each piece with a hammer.

After completing the work, pour sand onto the tile surface and spread it over the tile in such a way as to completely fill the joints. Then water the path, repeat the work again in a couple of days.

But if the site is too large or you are not sure that you can cope with this work, you can hire specialists who will lay the turnkey tile. The average cost per square meter is 400-600 rubles.